What Size Staples For 1/4 Inch Underlayment

SurePly ® Plywood Underlayment Installation Instructions

SurePly® Premium Plywood Underlayment & Materials Grooming

- Allow all materials used in your flooring installation to acclimate to the heated home surround, approximately 70°F, for 24 to 48 hours prior to apply.

- Store all panels on their 8' border (separately if possible) to allow equal air menses over the face and dorsum of the cloth.

- Examine each piece of SurePly® plywood underlayment using the Flex & Expect Test.

Follow these steps:

- Stand the panel vertically with its 4' edge on the floor and the panel face towards y'all (the staple/nail pattern volition be facing y'all).

- Grip the top panel border with 1 hand and firmly place the palm of your other paw against the face of the console.

- Pull the panel down approximately 4" - viii" with your top hand while simultaneously pressing forrad with the palm of your other mitt approximately iv" - 8" until a noticeable curve is in the console. Hold this position during inspection.

- With the console in this flexed position, thoroughly audit the entire panel surface for imperfections, which volition look like "bubbles" or "creases." In the rare instance that y'all observe such an imperfection, do not use the panel. Set it aside and contact Patriot Timber Products immediately for a resolution.

Structural SubFloor Training

- Install SurePly® plywood underlayment over a make clean, dry, level, original audio structural subfloor, or existing flooring.

- Thoroughly scrape, sweep, and vacuum the entire surface and strip whatsoever wax from the existing vinyl.

- Practice not use any agglutinative below SurePly® plywood underlayment.

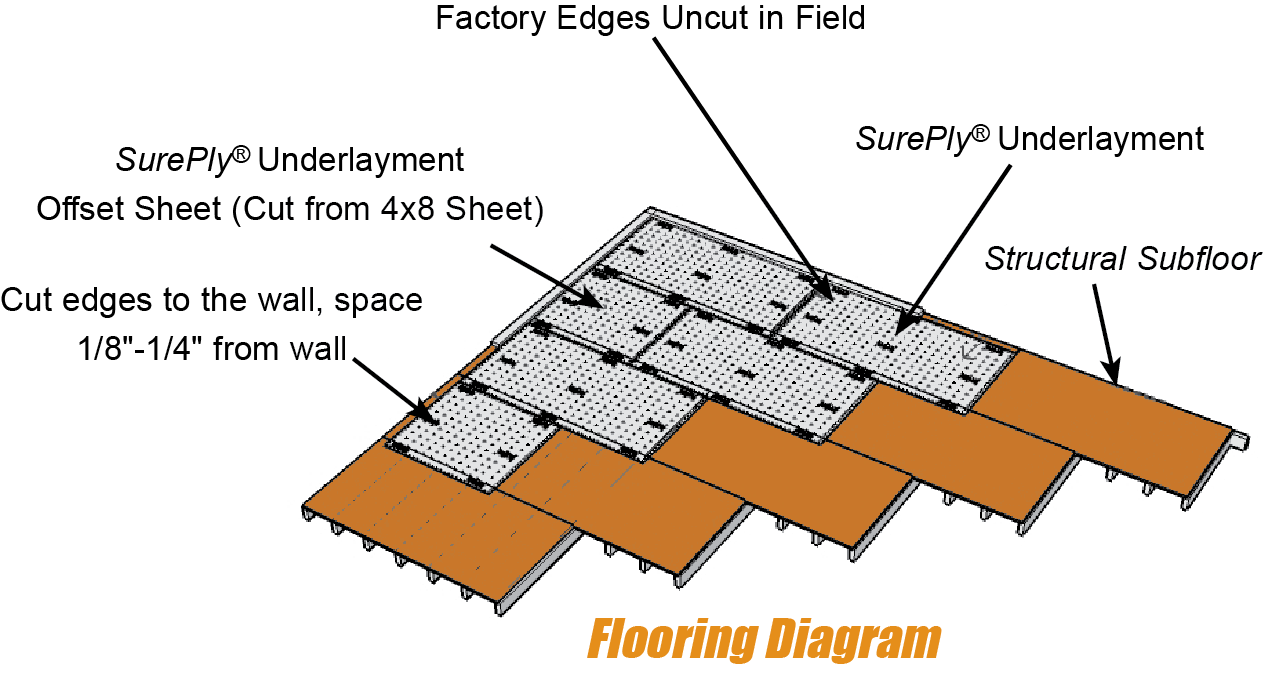

Positioning SurePly® Premium Plywood Underlayment

- Run SurePly® plywood underlayment panels perpendicular to the floor joists.

- Begin by laying out the floor in a corner of the room where you can get the greatest corporeality of coverage without having to cut the SurePly® plywood underlayment panels. The face with the nailing pattern is designed to go up.

- Position SurePly® plywood underlayment panels 1/eight" to ane/4" from the walls to allow for expansion.

- The panels should be cutting so that the manufactory edges go together at the seams in the field of the floor. Mitt cut outside edges for installation next to the walls.

- Stagger SurePly® plywood underlayment panels to create a ii" minimum outset between the SurePly® plywood underlayment panel and subfloor seams.

- There are ii methods for installing the SurePly® plywood underlayment. The commencement method, and our preference for all SurePly® plywood underlayment installations, is to install the panels without an expansion articulation and without a seam filler. We recommend you use this method for installation under vinyl, vinyl composite tile, luxury vinyl tile, ceramic tile, carpet, engineered flooring, and wood floors. For a SurePly® plywood underlayment installation without an expansion joint, lightly butt the panels together without applying any pressure so they barely touch at the joints.The second method is to install the SurePly® plywood underlayment panel with an expansion articulation and using a seam filler. If you choose to install the SurePly® plywood underlayment panel with a seam filler, leave a 5/64" gap, approx. the thickness of a nickel, between each panel. Then fill the seams according to the seam filler manufacturer's instructions.

- Cut and identify SurePly® plywood underlayment on the subfloor without whatever fasteners, or "dry fit" all panels get-go earlier beginning any fastening.

- Plywood underlayment panels should be laid in an start pattern every bit shown in the Flooring Diagram so that iv corners never directly intersect.

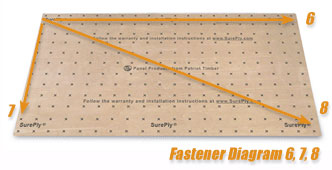

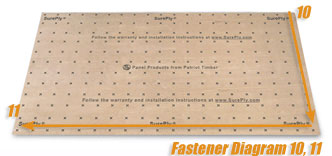

Fastening SurePly® Premium Plywood Underlayment

- Exercise not use any adhesive on the subfloor below SurePly® plywood underlayment.

- Nosotros recommend a pneumatic fastener tool that incorporates an adjustable depth-drive control to prevent fastener "blow-through" or "over-driving." If this feature is not available, adjust the air pressure level on the compressor to an appropriate level to avert fastener "over-driving" or "blow-through."

- You tin can fasten SurePly® plywood underlayment by selecting one of the following options: Galvanized coated chisel-point staples with a 1/iv" maximum crown or flathead wood screws treated with a moisture-resistant blanket (such equally galvanized or zinc). Exercise not use drywall screws. Exercise not select a fastener that is uncoated, cement or rosin-coated, as they may rust and discolor your finished floor. The length of the selected fastener should be a minimum of 5/8", but non so long that information technology protrudes through the bottom of the subfloor.

- Stand up on each plywood underlayment panel during fastening to ensure full contact with the subfloor. Any "crackling" or "popping" noises indicate debris is underneath the panel. Should this occur, finish the installation, remove and discard the panel, then scrape, sweep, and vacuum the subfloor again until all debris is removed.

- All fasteners should exist slightly countersunk below the surface of the new underlayment.

- Fasten the 8' edge showtime at 2" on centre - ane/2" from border - starting from the corner of the room. Leave an expansion joint of 1/8" to ane/4" betwixt the panel and the edge of the walls. Stand on the console to ensure flush contact with the structural subfloor, and practice not overdrive the fasteners.

- Return to the starting corner and fasten the iv' edge at 2" on centre - 1/ii" from the edge of the panel.

- Return to the starting corner and fasten the diagonal at 4" on eye to the opposing corner.

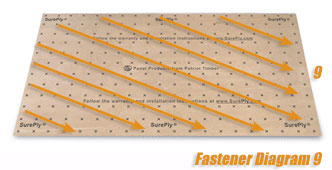

- Render to starting corner and fasten the "field" of the panel every 4" on centre working in a diagonal management across the confront of the SurePly® plywood underlayment panel. Make sure to put a fastener in each "ten" as you lot work diagonally across the console.

- Fasten the remaining 4' edge 2" on centre - 1/2" from the edge of the panel.

- Stop the sheet by fastening the remaining 8' edge ii" on center - ane/2" from the border of the panel. Note that the same procedure is used equally well for the offset sheet which would start the next row of underlayment.

Using Seam Filler with SurePly® Premium Plywood Underlayment

- If you lot choose to install the SurePly® plywood underlayment panel with an expansion joint, you must utilize a seam filler.* Check with your flooring supplier/manufacturer to be certain your seam filler is acceptable.

- Exercise not "floor-mix" seam fillers on tiptop of the SurePly® plywood underlayment console face. Mix the seam filler separately in a bucket.

- In one case the plywood underlayment panels are fastened, apply the seam filler and allow it to dry completely in accordance with the manufacturer's instructions. Allow sufficient curing time to completely dry the seam filler.

- Sand all joints with a belt or floor sander until level and smooth. Hand sanding is non sufficient.

- Do not oversand or "cup" the joints. Some additional application, drying time, and sanding may be necessary to smooth loftier or low spots.

- Later sanding, the seam filler should make full the seams and be affluent with the edges of the SurePly® plywood underlayment panels. We exercise not take "feathering" as a substitute for sanding the seam filler.

- Thoroughly vacuum the entire surface area to remove all droppings before installing the flooring covering.

*Annotation: You may get out an expansion joint without seam filler when SurePly ® plywood underlayment is used under rug, engineered floors, or wood floors.

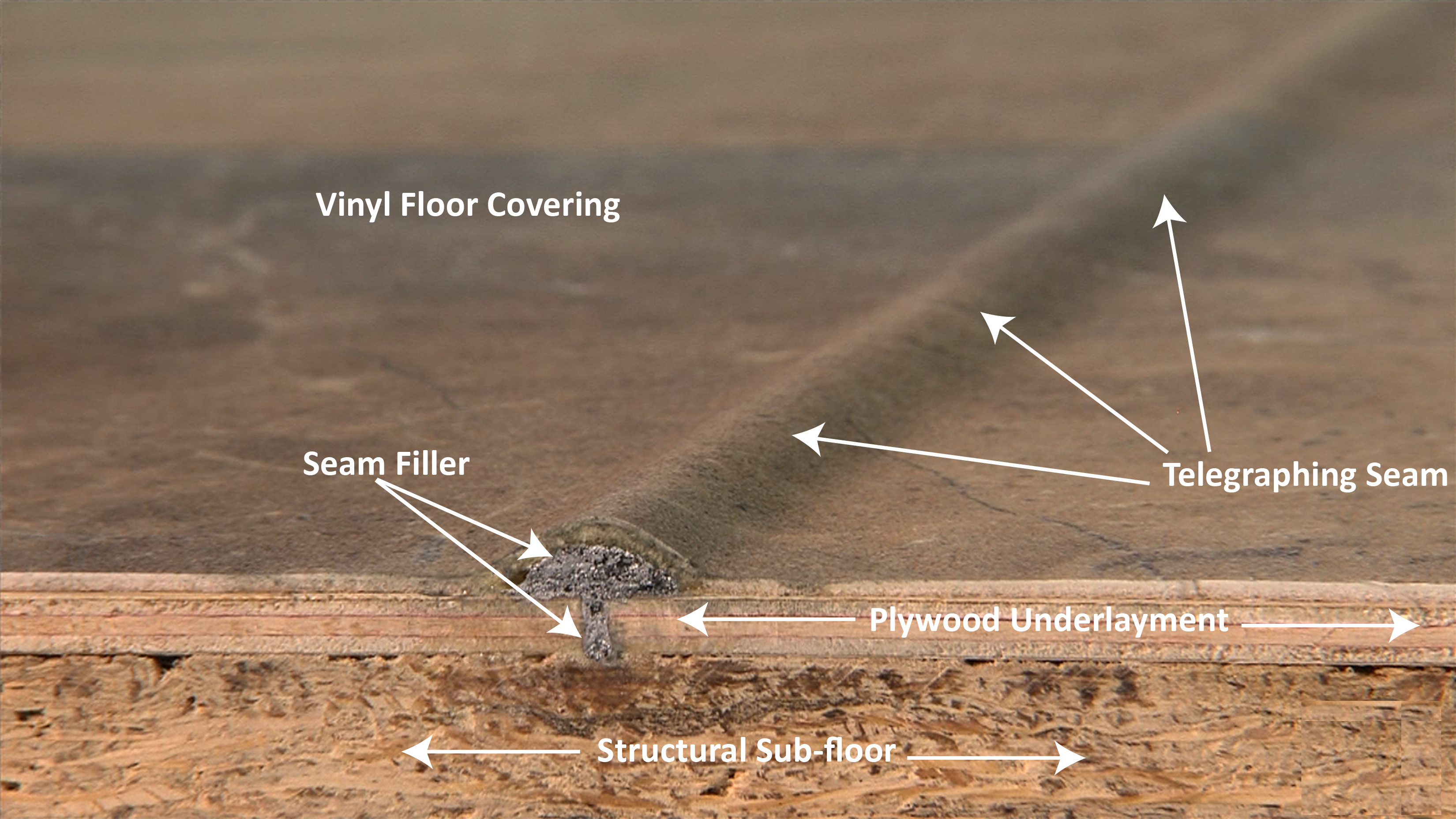

Causes of Telegraphing Seams and Panel Blow-Through

In our 50 plus years of experience, the majority of underlayment floor failures are due to telegraphing seams and fastener blow-through. Telegraphing seams and fastener accident-through are e'er the result of wrong installation. They are not caused by panel failure. At that place are many factors that can cause telegraphing seams. These are the about mutual:

- The use of too much seam filler

- Not assuasive the seam filler to dry out sufficiently

- Non sanding the seam filler polish and fifty-fifty with the plywood underlayment

- Panels beingness butted too tightly together

- Panels not properly acclimated

- Too high moisture content in floor environment

- Uneven subfloor

- Placing the fasteners more than ane/two" from the edges of the panels

- Inconsistent fastener depth and blow-through along the edges of the panels

Fastener blow-through is acquired past not properly adjusting the bulldoze depth or air pressure in your staple or boom gun, which can result in shooting the fastener completely through the underlayment. Nothing brusk of physical plywood failure such as delamination will exist warranted with regard to telegraphing seams.

Circumspection Regarding Point Overloading

Earlier moving or positioning any heavy object across the flooring (such every bit a large appliance), identify a minimum of 1/4" plywood on top of the completed floor to preclude signal overloading.

Phone call United states of america 336-299-7755 or E-mail Us for sales and technical information.

Return to Height

What Size Staples For 1/4 Inch Underlayment,

Source: https://www.patriottimber.com/sureply-installation-guide/

Posted by: winterreast1976.blogspot.com

0 Response to "What Size Staples For 1/4 Inch Underlayment"

Post a Comment